Flat Roof Skylight Guide with your own Timber Kerbs

A step-by-step guide to installing your Custom Flat Roof Skylight, when creating your own timber frame or kerb.

When you are installing your Custom Flat Roof Skylight, there a some considerations to first consider.

1) Ensure your roof is prepared correctly (more info in Roof Preparation Tips for you Skylight), & double check your structural opening vs the skylight size you order.

2) Your skylight must have a gradient for water run-off. This is 40mm for every 1000mm of skylight run - ideally across the shortest side.

3) Consider the weight of your skylight unit. You may need several people to assist the manual lifting & positioning of your roof light. Additionally, suction cups or mechanical lifting assistance may be required (trained operatives only).

Step 1: Firstly, check above advice & consult Roof Preparation Tips for your Skylight. If installing a Firestone Elevate EPDM rubber roof covering (or any EPDM) - ideally ensure the membrane is bonded to your deck first, then cut to fold back, ready for skylight kerb installation.

Check the internal dimensions of your roof opening, are the same as the dimensions on the product ordered. See the picture (right) for assistance on correctly measuring the opening.

Step 2: You now need to make your timber kerb, ready to house your flat roof skylight.

Firstly, the internal face of your kerb to be made, should be flush with the face of your structural opening (joists/upstand).

Your timber frame needs to be 75mm wide, & 150mm in height. Keep in mind the minimum gradient of 1 in 40mm, ideally across the shortest run, the length of the skylight (if not square), running parallel with your gutter run.

The 75mm x 150mm can be made up of multiple pieces, provided they are secure and well fitted.

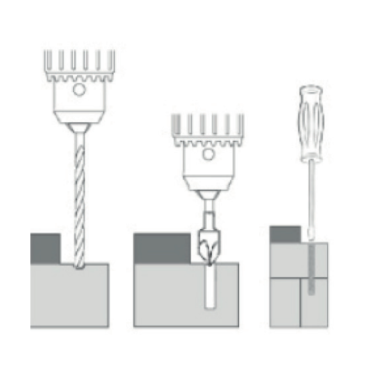

Step 3: Secure your 75mm x 150mm timber frame into your deck or joist base, using the appropriate fixings.

Fixings at 400mm centres, 150mm from each corner. We advise planning, piloting & countersinking first, then fitting your fasteners. There must be no proud screw heads/fixings.

Step 4: You must now install a batten to house the top pane of your unit. The batten is to be secured to the exterior edge of your upstand (face of your batten will be flush with the outside of your timber kerb face).

The height of your batten should be 38mm, with a width of 50mm. Secure your batten using the same principles explained in step 3.

Step 5: Proceed to dress your roof covering (Firestone Elevate EPDM preferably) to the top of your kerb. Ensure strong adhesion.

You will need to flash/seal your external corners of your skylight. For your Firestone Elevate flashing, you will need you Quick Seam Flashing, see here for your guide on flashing external corners.

Step 6: Apply a continual bead of quality, low-modulus sealant to both top flat surfaces of your rebated kerb, as well as the corner of the rebated glass unit.

We advise clear CT1 sealant as an example of the type of sealant required.

Step 7: Carefully & safely position your triple glazed unit into position.

As mentioned previously, depending on the size of your skylight, you will need to consider its weight & use multiple peoples to assist in safe lifting.

Step 8: Using the palm of your hands, push down around the edge of the skylight, evenly compressing your sealant (don't force over pressing on the glazing overhang).

Step 9: Once the glazed unit is in place, apply a final bead of sealant to the underside of your skylight overhang, where it meets the top of your kerb and roof covering.

This will help defend against any capillary action of ingress & pulling away of your roof covering. You can now, gently clean your glass if needed (no harsh chemicals).

Well done, you've installed your triple glazed flat roof skylight!